Lead-acid traction batteries

As a long-time expert in the lead-acid battery industry, we know exactly what matters when it comes to choosing the right lead-acid battery. Because which battery is the best fit depends on the application, the operating conditions and the external influences. Trust us to find the perfect battery solution for your forklifts and other traction applications.

You are on the safe side with us, because our batteries are 100% from European production. This ensures shorter delivery times and compliance with European quality standards. At the same time, unique technical features enable maximum operational reliability and long battery service life. And we leave a smaller ecological footprint together with you.

The ultimate on the market

Allgäu Batterie® PRO

- Our quality battery for the highest demands

- Maximum capacity in a standardized cell vessel: 4-7% more capacity than Allgäu Batterie® ECO

- Longer service life than standard market quality

- Available in all common lead cell technologies (PzS, PzV, Aqualess, Power Square)

Cost-optimized

Allgäu Batterie® ECO

- Longer service life

- 4% more capacity than standard low-profile cells due to more electrolyte

- Maximized service life through improved cell design (reduced risk of corrosion and higher short-circuit strength)

- Cost-optimized battery for all applications

- Available as PzS

Don’t forget to fill with water:

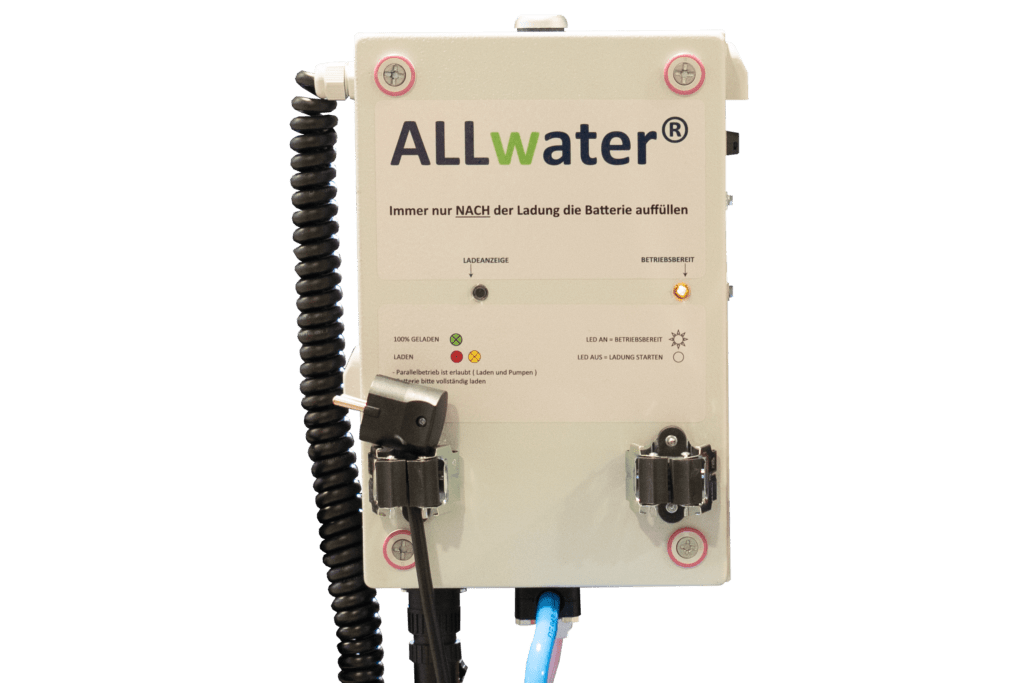

Now even easier with ALLwater®

Discover the battery- and/or mains-operated device for easily filling your battery with distilled water after charging.

Benefits of our lead-acid batteries

Aquamatic filter

Greater thread length

High quality trays

Battery terminal in sliding terminal design

Double tube feedthrough for electrolyte circulation (EUW)

Traction batteries of the premium series Allgäu Batterie® Pro meet the highest requirements. Compared to commercially available lead-acid batteries, the Allgäu Batterie® Pro combines the highest quality with powerful performance and maximum safety. And in combination with the ALLtrac® Plus high-frequency charging device, you get an energy package for traction applications that is second to none.

The Allgäu Batterie® Pro is available in four types. Depending on the intended use, we recommend the variant that is right for you:

PzS (DIN) / PzB (British Standard)

- PzS (Standard Armor Plate Battery): Dimension series L

- PzB: British dimensions (dimension series E: narrower than PzS)

- No technological difference

PzV / PzVB (Gel)

- maintenance-free

- suitable for sensitive applications (pharmaceutical, food, chemical)

- no escape of corrosive liquid

- no water filling or artificial venting

Aqualess

- Extension of the interval for water filling up to 12 weeks

- Prerequisite: suitable HF charging device (adapted characteristic curve, reduced charging factor)

Power Square

- modified plate design: increased performance, extended travel time per discharge cycle

The new one in the family

Allgäu Batterie® ECO

As a cost-optimized solution with 4% more capacity than the standard low-profile cell on the market, the Allgäu Battery® ECO is suitable for tough use. Due to the lower electrolyte level, the Allgäu Battery® ECO is particularly well protected against corrosion and guarantees you a reliable energy supply for your forklift. In addition, the Allgäu Battery® ECO has a higher short-circuit resistance than a standard battery due to the larger mud space.

By the way: With the high-frequency chargers from the ALLgo® series, you can get the most out of your Allgäu Batterie® ECO.

Water filling made easy: ALLwater®

Filling a battery with distilled water has never been easier: With ALLwater® we offer you a battery- and/or mains-powered device with which clean water can be pumped from a water tank into a battery in accordance with DIN 43530 – quickly, safely and very easily.

Your benefits

- All-in-one solution with easy handling

- Parallel operation of charging and pumping

- great savings in personnel and time

- easy to convert

- discharge monitor to protect the battery

4 Versions

The ALLwater® can be attached to an IBC barrel (IBC version), mounted on a hand truck (Mobile version), screwed to a wall (Wall version) or set up on a workbench (Stand version).

Our answers to your questions

Contact now

CHRISTIAN HÖSL

Account manager

Lead-acid traction batteries

+49 8374 24124-61

Learn more